Equipment Testing

The Challenge

The Challenge

The Navy must continually improve diving capabilities while maintaining diver safety.

The Solution

The Solution

In modern times, NEDU’s most important task is evaluating diving gear diving gear for use by Navy divers, Explosive Ordnance Disposal (EOD), and Special Forces. NEDU’s exhaustive testing ranges from ensuring equipment safety and reliability to studying means of strengthening equipment for harsh environments. The examples on display here are just a few of the hundreds of pieces of equipment NEDU has evaluated and certified for Navy use.

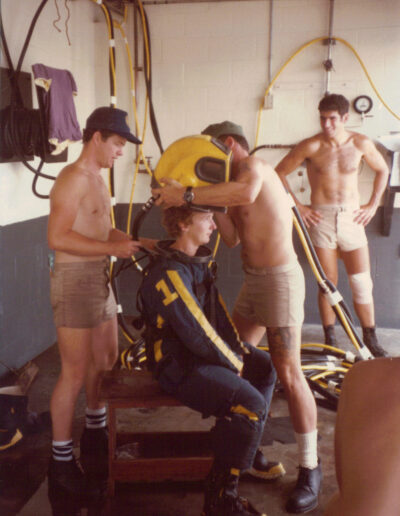

Surface-Supplied Diving Systems

A surface-supplied diving system provides breathing air to a diver through an umbilical (hose) connected to control equipment on the surface. Most Navy diving operations use surface-supplied systems. In the early 1970s, NEDU initiated a project to modernize the MK V system, in service since 1916. NEDU developed, tested, and certified a new system, the MK 12 Surface-Supplied Diving System (SSDS), which was adopted in 1985. NEDU also led the subsequent modernization effort, evaluating and adapting a commercial helmet for use as the MK 21 helmet.

MK 12 Surface-Supported Diving System

NEDU designed the MK 12 after identifying a need for an updated diving system. Following a four-year development period, NEDU conducted three years of testing before the system was approved for use. The MK 12 provided divers with greater mobility, flexibility, and comfort compared to the retired MK V.

MK 21 Helmet

The MK 21 helmet replaced the MK 12 system in 1993. Instead of designing a system, the Navy chose to adapt a commercial helmet, the Superlite 17B, to Navy specifications. NEDU conducted the analysis of the helmet, identified changes needed to meet Navy standards, and certified the modified design.

Unlike its predecessors, the MK 21 system does not include a standard diving suit. It can be used with different types of suits and gear.

MK 14 Closed-Circuit Saturation Diving System

This saturation diving system operates from an underwater saturation diving bell, rather than from the surface. NEDU developed it in the 1970s to support saturation diving projects. The system improved the Navy’s saturation diving capabilities by streamlining the equipment needed, reducing costs, and increasing work time underwater.

Diving Masks

The Navy uses specialized diving masks for some types of surface-supplied diving. In warm, uncontaminated environments, diving masks offer a lightweight alternative to the typical surface-supplied system. NEDU tests commercial masks for Navy use, recommending safety modifications and certifying Navy mil-spec versions.

Jack Browne Mask

The Navy used the Jack Browne lightweight mask for shallow water diving from World War II through the late 1970s. NEDU evaluated the mask on multiple occasions. While assessments in the 1950s affirmed its usefulness, by 1978 NEDU determined the aging mask could no longer support intensive diving operations. The Navy limited its use to 40 feet before retiring it in the 1980s.

MK 1 Mask

The MK 1 lightweight mask supported both air and mixed gas operations, could be used to 300 feet, and provided voice communications. It is a modified version of the commercial Kirby Morgan band mask, which NEDU tested in the early 1970s. The Navy adopted it after modifications recommended by NEDU’s assessment were implemented.

Rebreathers

NEDU began experimenting with rebreathers as early as World War II. A rebreather is a type of underwater breathing apparatus (UBA) that recycles a diver’s breathing mixture by scrubbing it of carbon dioxide. Navy EOD and Special Forces use rebreathers for covert operations. Compared to surface-supplied diving equipment, rebreathers are more compact, offer greater mobility, and do not produce visible gas bubbles. NEDU’s work with rebreathers has significantly expanded the capabilities of EOD and Special Forces divers.

MK 11 Rebreather

NEDU evaluated the MK 11 rebreather in the 1970s, testing everything from overall unit safety to the life expectancy of the carbon dioxide scrubbing canisters.

MK 15 Rebreather

After the Navy purchased the MK 15 rebreather commercially in 1980, NEDU tested and certified it for use by Navy Special Forces. NEDU also developed new decompression tables to use with the MK 15, as the device’s ability to keep the oxygen level in the breathing mixture constant meant standard tables could not be used.

MK 16 Rebreather

Following successful testing by NEDU in the early 1980s, the Navy adopted the MK 16 rebreather (an improved version of the MK 15) to support Explosive Ordnance Disposal (EOD) operations. The MK 16 rebreather’s low magnetic output keeps EOD divers safe when performing work that might involve magnetically-detonated mines.

Diving Suits

Divers frequently work in cold, contaminated, or physically hazardous environments. Since introducing the first neoprene suits in the early 1950s, NEDU has developed and tested improved diving suits to provide physical and thermal protection to divers.

Wet Suits

Post World War II, NEDU faced the challenge of keeping divers warm. Staff repurposed an aviator’s neoprene exposure suit, which had its tester perspiring 1.5 hours into a cold dive. Through additional experimentation, NEDU tested neoprene thickness and overall design to maximize thermal and physical protection.

Hot Water Suits

Thermal protection is especially critical at greater depths (water becomes cold with depth), when breathing helium (which draws warmth from the diver’s body), or during saturation dives (which last several hours at deep depths). Hot water suits continually bathe divers in hot water from the surface, keeping them toasty warm.